Cement how bad it is for the environment?

Cement one of the active ingredients in concrete and is the one of the biggest producers of Co2 emissions in the world right now, contributing 5% of the world’s total Co2 emissions.

50% of the Co2 emissions each year come from the chemical process of creating Cement; the other 50% comes from burning fuel in the process.

Cement creation in 3 basic steps:

1.) Mix limestone and clay in a giant rotating kiln

2.) The heat the kiln to extreme temperatures breaking down the product into a material called Clinker

3.) Add gypsum and limestone with the clinker, mix together to create Portland cement, the main ingredient in concrete we use today.

Fly ash vs. Cement

Fly ash is a by-product from burning coal at power plants that usually gets buried at landfill sites. Fly ash is recognized as an environmentally friendly material while being mixed with cement because it is a by-product with low embodied energy. We are utilizing fly ash in combination with cement in our concrete here in Calgary. In doing so we hope to make a positive step forward in environmental change.

Here are some of the main benefits of using fly ash:

• Cold weather resistance

• Can produce a higher Mpa concrete strength over time

• It can be used as an admixture

• Shrinkage is considerably less helps with crack prevention

• Increased density and durability

• Improvements in workability

• Decreases permeability and bleeding

• Can have a low water to cement ratio better for pouring in colder conditions

Recycled crushed concrete

Where we can we try and use recycled crushed concrete where we can as filler for out sub-bases, without compromising our sub-base compaction. This helps the environment in a couple different ways.

• Relying on mines to produce new crushed gravel all the time

• Allot of the concrete work we rip up we can take to the recycling plant and get back crushed

• Better than having the used concrete waste sent to landfills

LVL Lumber

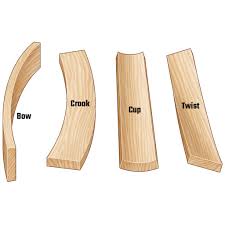

Envirocrete Inc. Calgary uses LVL lumber (laminated veneer lumber) for a large majority of our formwork, these are more durable and longer lasting than traditional pine lumber and can be used for years if looked after well, compared to pine lumber that is only good for a few times before it warps and bows and needs to be thrown out.

Also when pouring concrete walls, stairs, and planters we build our formwork shutters out of proper concrete form-ply that is reusable multiple times. Even though it's more expensive it gives a smoother flatter more consistent finish resulting in a better product for our customers.

Chemical run off into drains

When pressure-washing driveways we always make sure we build dams around the curb to catch any chemical run off. This is especially important with washing exposed aggregate as allot of cement needs to be removed from the top layer to expose all the aggregate.

We built this company Envirocrete here in Calgary Alberta with the intent to be more mindful and makes positive changes towards a sustainable future for the environment.

Living so close to the beautiful Rocky Mountains with its incredible lakes, mountains, forests, and wildlife we would like to help create a better future. If you would like to talk more about ways we can improve or have any questions feel free to reach out to us here at Envirocrete concrete services Inc.